Telephone:0086 15613734542

Cell phone:0086 15613734542

Mail:15613734542@163.com

Wechat:zsyjtdsz

For patients with dental issues, it’s common to delay visiting the dentist until the problem becomes unbearable. One major concern is the anxiety about surgical outcomes. However, with 3D printing technology gradually advancing into precision medical applications, even less-skilled doctors can now perform dental implant surgeries with significantly reduced difficulty.

Below, let’s briefly explain how resin 3D printing technology—currently the most widely used in dentistry—plays a role in surgical planning and surgical guides!

Patient Clinical Presentation

(Tooth #9 central incisor, #6 canine, #7 lateral incisor - #8 central incisor)

he patient’s tooth #9 exhibited mobility of a cast metal post, while teeth #6 to #8 were fitted with a dental bridge. Microscopic examination revealed a horizontal crack 2 mm below the gum line on the root of tooth #8, with the remaining crown and post-core retained in the crown.

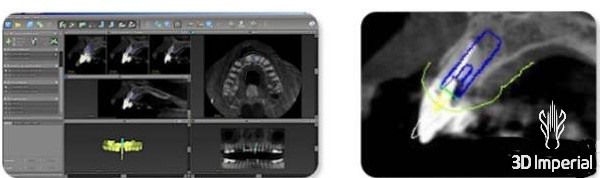

Preoperative Implant Assessment

Using Dental Wings coDiagnostiX surgical planning software, the implant positioning was determined. The surgical planning focused on preserving the buccal plate, engaging sufficient apical bone, and ensuring the prosthetic platform aligned harmoniously with the existing crown position.

Preoperative Preparation – Temporary Abutment and Crown

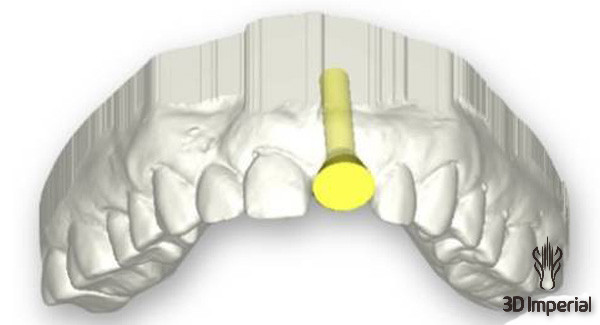

After completing the surgical plan, the next goal was to produce the temporary abutment and crown. The modeling of these components was achieved using coDiagnostiX [CDX] software, which can export the 3D model as an STL file for 3D printing, as shown below

From left to right, you’ll notice that the software converts the scan results into a 3D model, then performs a Boolean operation to create an implant replica along with its coronal projection.

The resulting cylindrical bone screw socket provides a base position for the manufacturer's implant, and users can add a crown to this base.

Once the STL files for the temporary abutment and crown were generated, the Formlabs 2 desktop printer used gray resin to print a precise temporary abutment socket.

Normally, the doctor would proceed directly with the implant surgery. However, with this highly accurate preoperative model, the doctor could first perform a surgical rehearsal on the abutment.

During the Surgery:

The coDiagnostiX modeling software was also used to create a surgical guide for the implant screw placement. The guide was printed using the Formlabs Dental SG desktop printer.

By utilizing 3D-printed pre-planned models and surgical guides to fabricate implant temporary abutments and crowns, digital surgical planning technology ensures precision and efficiency. The preoperatively customized abutment matched the patient’s post-extraction crown as accurately as expected.